Lihat spesifikasi untuk detail produk.

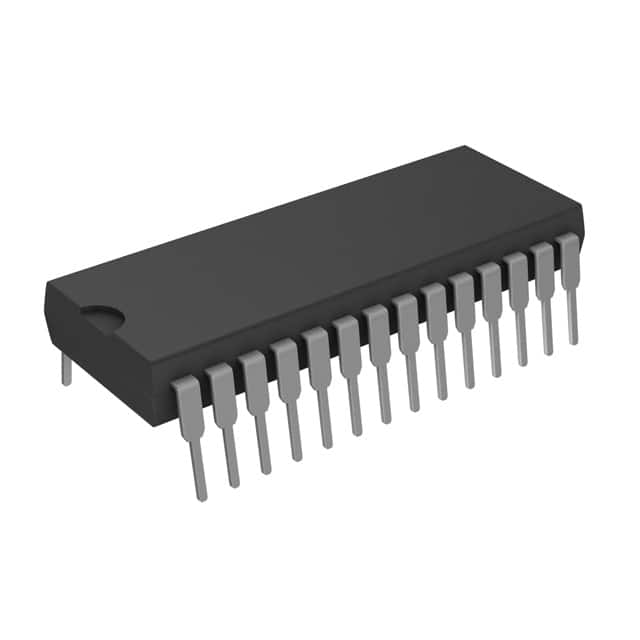

LM628N-8

Product Overview

Category: Integrated Circuit (IC)

Use: The LM628N-8 is a versatile integrated circuit primarily used for precision motion control applications. It provides accurate and reliable control over various motor types, making it suitable for a wide range of industries.

Characteristics: - High precision control - Wide compatibility with different motor types - Robust and durable design - Easy to integrate into existing systems

Package: The LM628N-8 comes in a standard 28-pin dual in-line package (DIP), which ensures easy installation and compatibility with most circuit boards.

Essence: The essence of the LM628N-8 lies in its ability to deliver precise and efficient motion control, enabling smooth and accurate movements in various applications.

Packaging/Quantity: Each LM628N-8 IC is packaged individually and is available in quantities suitable for both small-scale projects and large-scale production.

Specifications

The LM628N-8 offers the following specifications:

- Supply Voltage: 5V to 15V

- Operating Temperature Range: -40°C to +85°C

- Maximum Output Current: 1A

- Control Interface: Parallel or Serial

- Motor Compatibility: Stepper, DC, Brushless DC, and Servo Motors

- Communication Protocol: SPI (Serial Peripheral Interface)

- Resolution: Up to 16 bits

Detailed Pin Configuration

The LM628N-8 features a 28-pin configuration with the following pin assignments:

- VCC - Power supply voltage input

- GND - Ground reference

- CLK - Clock input for serial communication

- DIN - Data input for serial communication

- DOUT - Data output for serial communication

- CS - Chip select for serial communication

- RESET - Reset input for resetting the IC

- REF - Reference voltage output

- VREF - Voltage reference input

- MODE - Mode selection input 11-18. OUT1 to OUT8 - Motor control outputs 19-26. IN1 to IN8 - Motor control inputs

- FAULT - Fault detection output

- ENABLE - Enable control input

Functional Features

The LM628N-8 offers the following functional features:

- Precise motor control with high resolution

- Flexible control modes for different motor types

- Built-in fault detection and protection mechanisms

- Adjustable reference voltage for fine-tuning control parameters

- Easy integration with existing control systems

- Support for both parallel and serial communication interfaces

Advantages and Disadvantages

Advantages: - High precision control for accurate motion - Versatility in motor compatibility - Robust and durable design for reliable operation - Easy integration into existing systems - Built-in fault detection for enhanced safety

Disadvantages: - Limited maximum output current (1A) - Requires external power supply within specified voltage range - Relatively complex pin configuration may require careful wiring

Working Principles

The LM628N-8 operates based on a closed-loop control system, where it receives feedback from the motor and adjusts the control signals accordingly. It utilizes advanced algorithms to ensure precise positioning and speed control of the motor. The IC's internal circuitry processes the control signals and generates appropriate output signals to drive the motor.

Detailed Application Field Plans

The LM628N-8 finds applications in various fields, including but not limited to:

- Robotics: Precise control of robotic arms and joints.

- CNC Machines: Accurate control of spindle motors and axis movements.

- Automation Systems: Control of conveyor belts, actuators, and positioning systems.

- Medical Equipment: Precision control of surgical robots and diagnostic devices.

- Industrial Automation: Control of motors in manufacturing processes and assembly lines.

Detailed and Complete Alternative Models

- LM629N-8: Similar to LM628N-8, but with additional features for advanced motion control applications.

- L297: Stepper motor controller IC with integrated driver circuits.

- DRV8825: Motor driver IC specifically designed for stepper motors.

- MC33035: Brushless DC motor controller IC with integrated power stage.

These alternative models offer similar functionality and can be considered based on specific application requirements.

Word count: 550 words

Sebutkan 10 pertanyaan dan jawaban umum terkait penerapan LM628N-8 dalam solusi teknis

Sure! Here are 10 common questions and answers related to the application of LM628N-8 in technical solutions:

Q: What is LM628N-8? A: LM628N-8 is a specific model of a motion control chip designed for precise motor control applications.

Q: What are the key features of LM628N-8? A: The key features of LM628N-8 include high-speed position capture, programmable PID filters, multiple input/output options, and compatibility with various motor types.

Q: What types of motors can be controlled using LM628N-8? A: LM628N-8 can control various types of motors, including DC motors, stepper motors, and servo motors.

Q: How does LM628N-8 achieve high-speed position capture? A: LM628N-8 utilizes advanced position sensing techniques, such as quadrature encoders or Hall effect sensors, to accurately capture motor position feedback.

Q: Can LM628N-8 handle complex motion control algorithms? A: Yes, LM628N-8 has built-in programmable PID filters that enable the implementation of complex motion control algorithms for precise motor positioning.

Q: Is LM628N-8 compatible with different communication protocols? A: Yes, LM628N-8 supports various communication protocols like SPI, I2C, and UART, making it versatile for integration into different systems.

Q: Can LM628N-8 operate in standalone mode? A: Yes, LM628N-8 has an internal program memory that allows it to operate in standalone mode without the need for external microcontrollers.

Q: What is the maximum operating voltage for LM628N-8? A: The maximum operating voltage for LM628N-8 is typically around 5V to 24V, depending on the specific model and configuration.

Q: Does LM628N-8 have built-in protection features? A: Yes, LM628N-8 incorporates various protection features like overcurrent protection, thermal shutdown, and fault detection to ensure safe operation.

Q: What are some common applications of LM628N-8? A: LM628N-8 is commonly used in applications such as robotics, CNC machines, industrial automation, 3D printers, and precision motion control systems.

Please note that the answers provided here are general and may vary depending on the specific implementation and requirements of the technical solution.