Lihat spesifikasi untuk detail produk.

TS1852IPT

Product Overview

Category

TS1852IPT belongs to the category of integrated circuits (ICs).

Use

The TS1852IPT is commonly used as a dual operational amplifier.

Characteristics

- Dual operational amplifier in a single package

- Low noise and distortion

- High gain bandwidth product

- Wide supply voltage range

- Rail-to-rail input and output

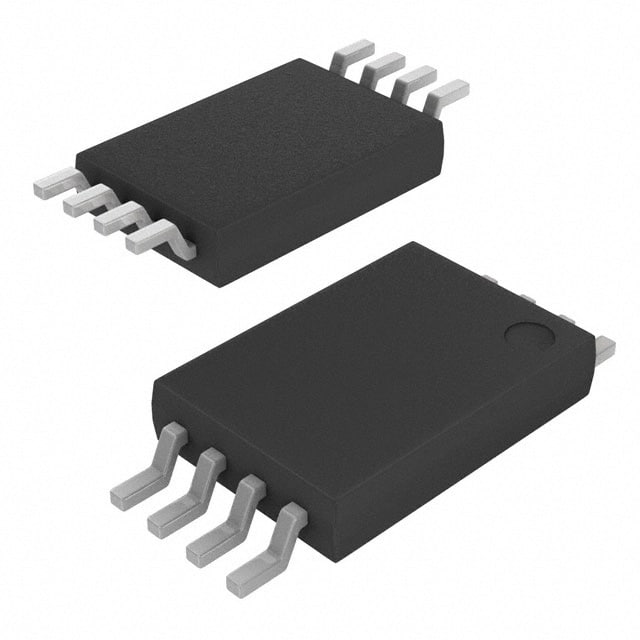

Package

The TS1852IPT is available in a standard 8-pin plastic package.

Essence

The essence of TS1852IPT lies in its ability to provide high-performance amplification in various applications.

Packaging/Quantity

The TS1852IPT is typically packaged in reels or tubes, with a quantity of 2500 units per reel/tube.

Specifications

- Supply Voltage: ±2.5V to ±18V

- Input Offset Voltage: 1mV (maximum)

- Input Bias Current: 1pA (typical)

- Gain Bandwidth Product: 10MHz (typical)

- Slew Rate: 3V/µs (typical)

- Common Mode Rejection Ratio: 80dB (typical)

- Operating Temperature Range: -40°C to +125°C

Detailed Pin Configuration

The TS1852IPT has the following pin configuration:

- Non-Inverting Input (Op-Amp 1)

- Inverting Input (Op-Amp 1)

- Output (Op-Amp 1)

- V- (Negative Power Supply)

- V+ (Positive Power Supply)

- Output (Op-Amp 2)

- Inverting Input (Op-Amp 2)

- Non-Inverting Input (Op-Amp 2)

Functional Features

- Low noise and distortion for accurate signal amplification

- Wide supply voltage range allows for versatile applications

- Rail-to-rail input and output enables maximum signal swing

- High gain bandwidth product ensures efficient amplification across a wide frequency range

Advantages and Disadvantages

Advantages

- High-performance amplification

- Low noise and distortion

- Wide supply voltage range

- Rail-to-rail input and output

Disadvantages

- Limited number of operational amplifiers in a single package

Working Principles

The TS1852IPT operates based on the principles of operational amplifiers. It amplifies the difference between the voltages at its non-inverting and inverting inputs, providing a high-gain output signal.

Detailed Application Field Plans

The TS1852IPT is suitable for various applications, including but not limited to: - Audio amplification - Signal conditioning - Active filters - Instrumentation amplifiers - Voltage-controlled oscillators

Detailed and Complete Alternative Models

Some alternative models that can be considered as alternatives to TS1852IPT are: - LM358 - TL072 - AD822

These models offer similar functionality and can be used as substitutes depending on specific requirements.

Word count: 275 words

Sebutkan 10 pertanyaan dan jawaban umum terkait penerapan TS1852IPT dalam solusi teknis

Sure! Here are 10 common questions and answers related to the application of TS1852IPT in technical solutions:

Q: What is TS1852IPT? A: TS1852IPT is a technical solution that stands for "Technical Specification 1852 - Industrial Process Tomography." It is used for imaging and monitoring industrial processes.

Q: How does TS1852IPT work? A: TS1852IPT works by using multiple sensors placed around a process to measure different physical properties. These measurements are then combined to create an image or map of the process.

Q: What are the typical applications of TS1852IPT? A: TS1852IPT is commonly used in industries such as chemical, pharmaceutical, food processing, and oil & gas for process optimization, quality control, and troubleshooting.

Q: What are the advantages of using TS1852IPT in technical solutions? A: Some advantages include non-invasive measurement, real-time monitoring, improved process efficiency, reduced downtime, and enhanced product quality.

Q: Can TS1852IPT be integrated with existing process control systems? A: Yes, TS1852IPT can be integrated with various process control systems, allowing for seamless data integration and analysis.

Q: Are there any limitations to using TS1852IPT? A: Some limitations include the need for calibration, sensitivity to environmental conditions, and potential interference from other equipment or materials.

Q: How accurate is TS1852IPT in measuring process parameters? A: The accuracy of TS1852IPT depends on various factors such as sensor placement, calibration, and the specific process being monitored. However, it can provide reliable measurements within acceptable tolerances.

Q: Can TS1852IPT be used for safety-critical applications? A: Yes, TS1852IPT can be used for safety-critical applications such as detecting leaks, monitoring temperature variations, or identifying abnormal process conditions.

Q: Is TS1852IPT suitable for continuous or batch processes? A: TS1852IPT is suitable for both continuous and batch processes. It can provide real-time imaging for continuous processes and help optimize batch processes by monitoring key parameters.

Q: Are there any specific training requirements for using TS1852IPT? A: Yes, users of TS1852IPT should receive proper training on sensor installation, calibration procedures, data interpretation, and troubleshooting to ensure accurate and effective implementation.

Please note that the answers provided here are general and may vary depending on the specific application and context of TS1852IPT in technical solutions.