Lihat spesifikasi untuk detail produk.

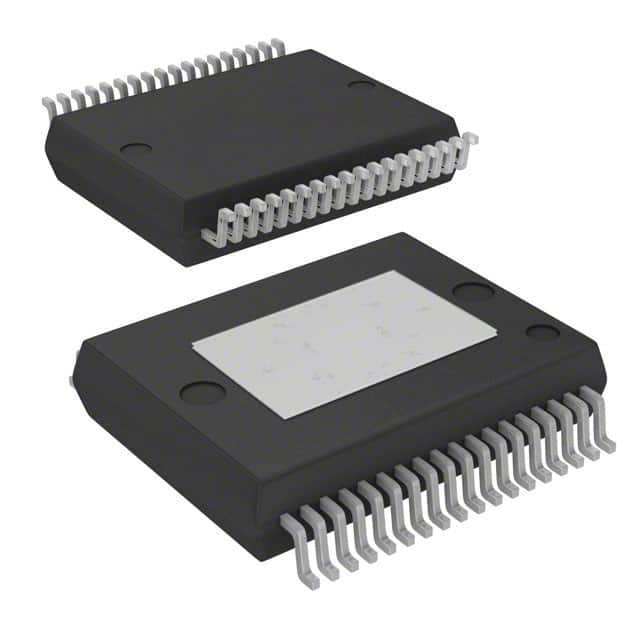

L6258EX

Product Overview

Category: Integrated Circuit (IC)

Use: Motor Driver

Characteristics: High voltage, high current, bipolar stepper motor driver

Package: PowerSO-20

Essence: The L6258EX is a versatile motor driver IC designed for driving bipolar stepper motors. It offers high voltage and high current capabilities, making it suitable for a wide range of applications.

Packaging/Quantity: The L6258EX is available in a PowerSO-20 package, which contains one IC per package.

Specifications

The L6258EX has the following specifications:

- Supply Voltage Range: 7V to 52V

- Output Current: Up to 2.8A per phase

- Maximum Step Frequency: 100 kHz

- Built-in Protection Features: Thermal shutdown, overcurrent protection, undervoltage lockout

Detailed Pin Configuration

The L6258EX features a PowerSO-20 package with the following pin configuration:

- VCP - Charge Pump Capacitor Positive Supply Voltage

- CP1 - Charge Pump Capacitor Connection

- CP2 - Charge Pump Capacitor Connection

- GND - Ground

- VREF - Reference Voltage Output

- REF - Reference Voltage Input

- OUT1 - Phase 1 Output

- OUT2 - Phase 2 Output

- OUT3 - Phase 3 Output

- OUT4 - Phase 4 Output

- IN1 - Phase 1 Input

- IN2 - Phase 2 Input

- IN3 - Phase 3 Input

- IN4 - Phase 4 Input

- VCC - Logic Supply Voltage

- EN - Enable Input

- MS1 - Microstep Selection Input 1

- MS2 - Microstep Selection Input 2

- MS3 - Microstep Selection Input 3

- GND - Ground

Functional Features

The L6258EX offers the following functional features:

- Microstepping: The IC supports microstepping modes, allowing for smoother and more precise motor control.

- Current Control: It provides adjustable current control to optimize motor performance and power consumption.

- Protection Mechanisms: The L6258EX incorporates various protection features such as thermal shutdown, overcurrent protection, and undervoltage lockout to ensure safe operation.

Advantages and Disadvantages

Advantages: - High voltage and high current capabilities - Versatile motor driver suitable for a wide range of applications - Built-in protection features enhance safety - Adjustable current control for optimized motor performance

Disadvantages: - Limited maximum step frequency compared to some other motor drivers - Requires external charge pump capacitors for proper operation

Working Principles

The L6258EX operates by receiving control signals from a microcontroller or other control circuitry. These signals determine the desired motor movement and speed. The IC then generates the necessary drive signals to control the stepper motor's phases, enabling precise positioning and rotation.

Detailed Application Field Plans

The L6258EX can be used in various applications, including but not limited to:

- Robotics: The IC can be utilized in robotic systems that require precise motor control for movements and manipulations.

- CNC Machines: It is suitable for driving stepper motors in computer numerical control (CNC) machines, ensuring accurate positioning and smooth motion.

- 3D Printers: The L6258EX can be employed in 3D printers to control the movement of the print head and build platform, enabling precise layer-by-layer printing.

- Automated Equipment: It finds application in automated equipment where precise motor control is essential for tasks such as conveyor belt movement or robotic arm positioning.

Detailed and Complete Alternative Models

Some alternative models to the L6258EX that offer similar functionality are:

- L297: This IC combines a stepper motor controller and driver in a single package, simplifying the design of stepper motor control systems.

- DRV8825: It is a popular motor driver IC with adjustable current control and microstepping capabilities, suitable for various stepper motor applications.

- A4988: Another widely used motor driver IC that supports microstepping and offers adjustable current control for precise motor control.

These alternative models can be considered based on specific application requirements and design constraints.

Word count: 511 words

Sebutkan 10 pertanyaan dan jawaban umum terkait penerapan L6258EX dalam solusi teknis

Sure! Here are 10 common questions and answers related to the application of L6258EX in technical solutions:

Q: What is L6258EX? A: L6258EX is a high voltage stepper motor driver IC designed for use in various motion control applications.

Q: What is the maximum voltage that L6258EX can handle? A: L6258EX can handle a maximum voltage of up to 75V, making it suitable for high voltage stepper motor applications.

Q: Can L6258EX drive both bipolar and unipolar stepper motors? A: Yes, L6258EX can drive both bipolar and unipolar stepper motors, providing flexibility in motor selection.

Q: What is the maximum current that L6258EX can deliver to the stepper motor? A: L6258EX can deliver a maximum current of up to 5A to the stepper motor, allowing for high torque applications.

Q: Does L6258EX have built-in protection features? A: Yes, L6258EX includes built-in protection features such as overtemperature, overcurrent, and short-circuit protection.

Q: Can L6258EX be controlled using a microcontroller? A: Yes, L6258EX can be easily controlled using a microcontroller through its step and direction inputs.

Q: What is the typical operating frequency range of L6258EX? A: The typical operating frequency range of L6258EX is between 20kHz and 100kHz, allowing for precise motor control.

Q: Is L6258EX compatible with 3.3V logic levels? A: No, L6258EX operates with 5V logic levels, so level shifting may be required when interfacing with a 3.3V microcontroller.

Q: Can L6258EX handle microstepping? A: Yes, L6258EX supports microstepping up to 1/16th step resolution, enabling smoother and more precise motor movements.

Q: Are there any application examples for L6258EX? A: Yes, L6258EX can be used in various applications such as CNC machines, 3D printers, robotics, and industrial automation systems.

Please note that these answers are general and may vary depending on the specific implementation and requirements of your technical solution.