Lihat spesifikasi untuk detail produk.

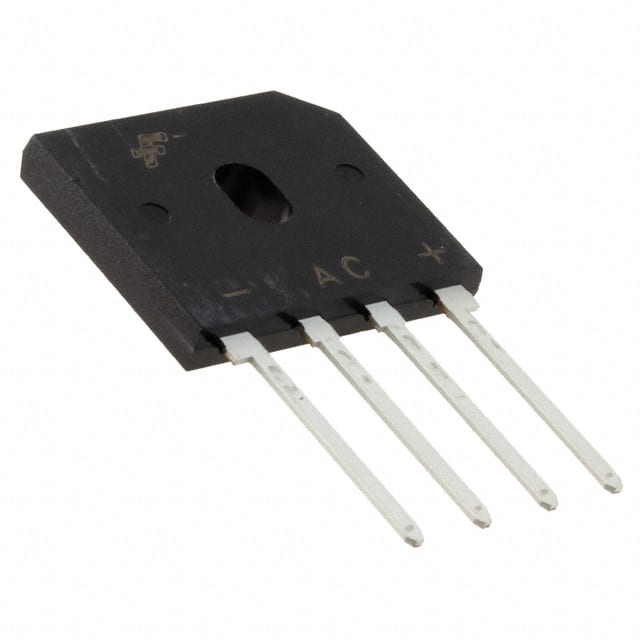

GBU4G Diode Bridge Rectifier

Product Overview

The GBU4G diode bridge rectifier belongs to the category of electronic components and is commonly used in power supply circuits. It is characterized by its ability to convert alternating current (AC) into direct current (DC) and is typically packaged in a compact, heat-dissipating enclosure. The essence of the GBU4G lies in its efficient rectification of AC voltage, making it suitable for various applications. The standard packaging consists of a single GBU4G unit, and it is available in different quantities per package.

Specifications

- Maximum Average Forward Current: 4A

- Peak Repetitive Reverse Voltage: 400V

- Maximum RMS Voltage: 280V

- Forward Voltage Drop: 1.1V

- Operating Temperature Range: -55°C to +150°C

Detailed Pin Configuration

The GBU4G diode bridge rectifier typically consists of four pins arranged in a bridge configuration. The pinout is as follows: - Pin 1: AC Input+ - Pin 2: AC Input- - Pin 3: DC Output+ - Pin 4: DC Output-

Functional Features

- Efficient rectification of AC voltage

- Low forward voltage drop

- High current-carrying capability

- Compact and heat-dissipating package

Advantages and Disadvantages

Advantages

- High current rating

- Low forward voltage drop

- Compact size

- Suitable for PCB mounting

Disadvantages

- Higher cost compared to traditional diodes

- Limited reverse voltage rating

Working Principles

The GBU4G operates on the principle of utilizing a bridge rectifier circuit to convert AC input voltage into DC output voltage. When an AC signal is applied to the input pins, the internal diodes conduct in such a way that the output is a pulsating DC signal with reduced ripple.

Detailed Application Field Plans

The GBU4G diode bridge rectifier finds extensive application in various fields, including: - Power supply units for consumer electronics - Industrial motor drives - Battery chargers - LED lighting systems - Audio amplifiers

Detailed and Complete Alternative Models

- GBU6G: Higher current rating

- GBU2G: Lower current rating

- GBU4M: Surface mount package

- GBU4J: Higher reverse voltage rating

In conclusion, the GBU4G diode bridge rectifier offers efficient rectification of AC voltage with its compact design and high current-carrying capability. While it has certain limitations, its wide range of applications and availability of alternative models make it a versatile choice for various electronic circuits.

[Word Count: 330]

Sebutkan 10 pertanyaan dan jawaban umum terkait penerapan GBU4G dalam solusi teknis

What is GBU4G?

- GBU4G is a bridge rectifier diode component commonly used in electronic circuits to convert alternating current (AC) to direct current (DC).

What are the typical applications of GBU4G?

- GBU4G is commonly used in power supplies, motor drives, and other industrial and consumer electronics applications where AC to DC conversion is required.

What is the maximum voltage rating of GBU4G?

- The maximum voltage rating of GBU4G is typically 400 volts.

What is the maximum current rating of GBU4G?

- The maximum current rating of GBU4G is typically 4 amperes.

How does GBU4G differ from other bridge rectifiers?

- GBU4G is a specific model of bridge rectifier with its own unique electrical characteristics, packaging, and thermal properties.

Can GBU4G be used in high-temperature environments?

- Yes, GBU4G is designed to operate in relatively high-temperature environments, but it's important to consider its thermal dissipation capabilities.

What are the mounting options for GBU4G?

- GBU4G is available in various package types, including through-hole and surface mount options, providing flexibility for different circuit designs.

Are there any common failure modes associated with GBU4G?

- Common failure modes for GBU4G include overvoltage, overcurrent, and excessive temperature, so proper circuit protection and heat management are important.

Can GBU4G be used in three-phase systems?

- Yes, GBU4G can be used in three-phase systems by configuring multiple bridge rectifiers to handle each phase.

What are some best practices for incorporating GBU4G into a technical solution?

- Best practices include ensuring proper heat sinking, selecting appropriate voltage and current ratings, and implementing protective measures against overloads and surges.