Lihat spesifikasi untuk detail produk.

FEP16DT

Product Category

FEP16DT belongs to the category of rectifier diodes.

Basic Information Overview

- Use: Rectification of alternating current (AC) to direct current (DC) in electronic circuits.

- Characteristics: High current capability, low forward voltage drop, and fast switching.

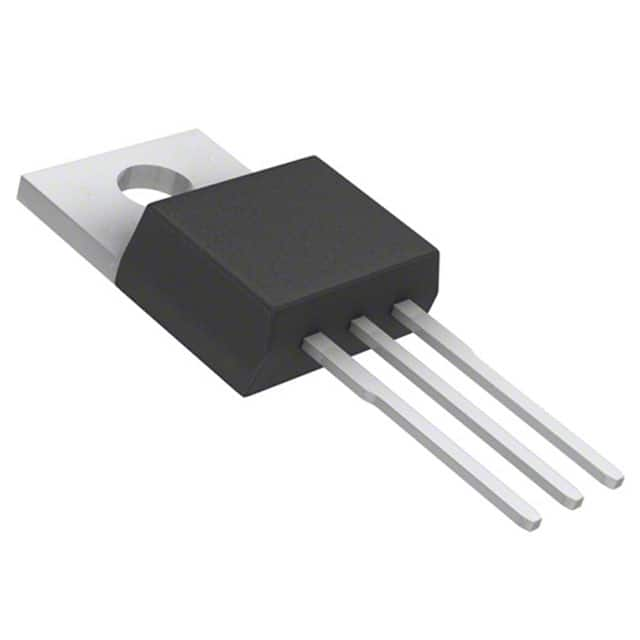

- Package: Typically available in a DO-214 package.

- Essence: FEP16DT is designed for use in power supplies, inverters, and other applications requiring rectification of AC to DC.

- Packaging/Quantity: Available in reels or tubes with varying quantities depending on manufacturer.

Specifications

- Maximum Average Forward Current: 16A

- Peak Reverse Voltage: 200V

- Forward Voltage Drop: 0.95V at 16A

- Reverse Leakage Current: 10μA

- Operating Temperature Range: -65°C to +175°C

Detailed Pin Configuration

The FEP16DT typically has two pins, anode and cathode, which are identified by a line on the cathode side of the diode symbol.

Functional Features

- High current capability allows for efficient rectification of high-power AC signals.

- Low forward voltage drop minimizes power loss and heat generation.

- Fast switching characteristics enable rapid response in electronic circuits.

Advantages and Disadvantages

Advantages: 1. High current capability suitable for power electronics applications. 2. Low forward voltage drop reduces power dissipation. 3. Fast switching characteristics enable efficient circuit operation.

Disadvantages: 1. Higher reverse leakage current compared to some alternative models. 2. Limited peak reverse voltage compared to higher voltage diodes.

Working Principles

FEP16DT operates based on the principle of semiconductor rectification, allowing current to flow in one direction while blocking it in the opposite direction. When forward-biased, it conducts current with minimal voltage drop, enabling efficient conversion of AC to DC.

Detailed Application Field Plans

FEP16DT is commonly used in: - Power supply units for consumer electronics and industrial equipment. - Inverters for renewable energy systems such as solar and wind power. - Motor drive circuits in industrial automation and electric vehicles.

Detailed and Complete Alternative Models

Some alternative models to FEP16DT include: - FR207: Similar specifications with a higher peak reverse voltage of 1000V. - MUR1560: Higher current capability and lower forward voltage drop. - UF4007: Lower forward voltage drop and lower reverse leakage current.

This comprehensive range of alternative models provides engineers with options to suit specific application requirements.

Word count: 398

Sebutkan 10 pertanyaan dan jawaban umum terkait penerapan FEP16DT dalam solusi teknis

What is FEP16DT?

- FEP16DT is a type of fluorinated ethylene propylene (FEP) material known for its high thermal stability, chemical resistance, and electrical insulation properties.

What are the key technical properties of FEP16DT?

- FEP16DT exhibits excellent dielectric strength, low dissipation factor, wide temperature range (-200°C to 200°C), and exceptional resistance to chemicals and solvents.

How can FEP16DT be applied in electrical applications?

- FEP16DT is commonly used as an insulating material for wires, cables, and electronic components due to its high dielectric strength and electrical insulation properties.

In what ways can FEP16DT be utilized in chemical processing equipment?

- FEP16DT is often employed as a lining material for tanks, pipes, and valves in chemical processing equipment due to its resistance to corrosive chemicals and high temperatures.

What are the considerations for using FEP16DT in high-temperature environments?

- FEP16DT's wide temperature range and thermal stability make it suitable for applications in high-temperature environments, such as in industrial ovens and heat exchangers.

Can FEP16DT be used in medical devices?

- Yes, FEP16DT is biocompatible and can be utilized in medical devices such as catheters and surgical instruments due to its chemical inertness and non-toxic nature.

How does FEP16DT compare to other fluoropolymer materials like PTFE or PVDF?

- FEP16DT shares some similarities with PTFE in terms of chemical resistance but offers better clarity and flexibility. It also has higher continuous use temperature compared to PVDF.

Are there any limitations or compatibility concerns when using FEP16DT with other materials?

- FEP16DT may not be compatible with certain solvents or fuels, so compatibility testing should be conducted before use. It also has limited adhesion to other materials, which should be considered in bonding applications.

What are the best practices for processing and molding FEP16DT?

- FEP16DT can be processed using standard extrusion and injection molding techniques, and it is important to maintain proper melt temperatures and mold temperatures to achieve optimal properties.

What are the environmental considerations when using FEP16DT in technical solutions?

- FEP16DT is non-toxic and does not release hazardous substances during use, making it environmentally friendly. However, proper disposal methods should be followed to minimize environmental impact.