Lihat spesifikasi untuk detail produk.

DURF1040CT Product Overview

Introduction

The DURF1040CT is a semiconductor product that belongs to the category of Schottky diodes. This entry provides a comprehensive overview of the DURF1040CT, including its basic information, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Schottky diodes

- Use: Rectification and voltage clamping in various electronic circuits

- Characteristics: High current capability, low forward voltage drop, fast switching speed

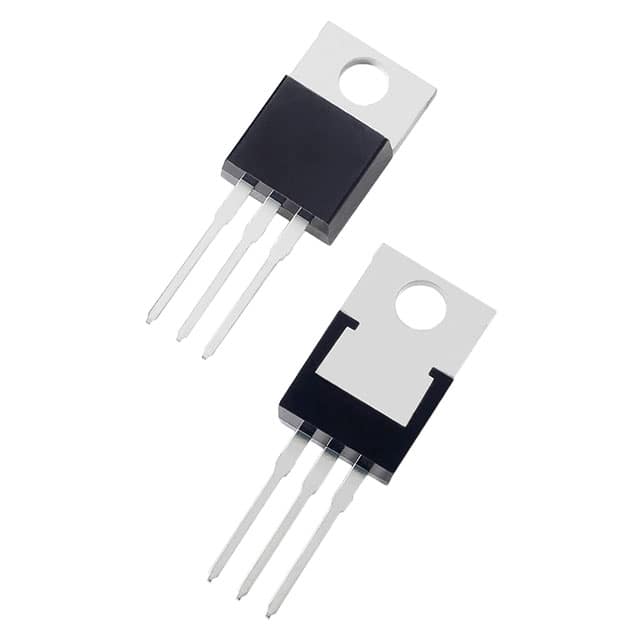

- Package: TO-220AB

- Essence: Semiconductor device for power applications

- Packaging/Quantity: Available in reels or tubes with varying quantities

Specifications

- Maximum Average Forward Current: 10A

- Peak Repetitive Reverse Voltage: 40V

- Forward Voltage Drop: Typically 0.55V at 5A

- Reverse Leakage Current: 50μA maximum at 40V

- Operating Temperature Range: -65°C to +175°C

Detailed Pin Configuration

The DURF1040CT has a standard TO-220AB package with three pins: 1. Anode (A) 2. Cathode (K) 3. Not connected (NC)

Functional Features

- High current capability allows for efficient power handling

- Low forward voltage drop minimizes power dissipation

- Fast switching speed enables rapid response in electronic circuits

Advantages and Disadvantages

Advantages

- Efficient power handling

- Low power dissipation

- Rapid response time

Disadvantages

- Limited reverse voltage capability compared to other diode types

- Sensitivity to temperature variations

Working Principles

The DURF1040CT operates based on the Schottky barrier principle, where the metal-semiconductor junction allows for fast switching and low forward voltage drop. When a forward bias is applied, the diode conducts current with minimal voltage loss, making it suitable for high-efficiency applications.

Detailed Application Field Plans

The DURF1040CT finds extensive use in the following application fields: - Switching power supplies - Voltage clamping circuits - Reverse polarity protection - Solar panel bypass diodes - Motor drive circuits

Detailed and Complete Alternative Models

For applications requiring similar characteristics, alternative models to the DURF1040CT include: - DURF2040CT: Higher peak repetitive reverse voltage - DURF3040CT: Lower forward voltage drop - DURF1540CT: Lower reverse leakage current

In conclusion, the DURF1040CT Schottky diode offers efficient power handling, fast switching speed, and low forward voltage drop, making it suitable for various electronic applications.

[Word Count: 398]

Sebutkan 10 pertanyaan dan jawaban umum terkait penerapan DURF1040CT dalam solusi teknis

What is DURF1040CT?

- DURF1040CT is a high-performance, thermally conductive adhesive tape used for bonding electronic components to heat sinks and other surfaces.

What are the key features of DURF1040CT?

- DURF1040CT offers excellent thermal conductivity, electrical insulation, and adhesion to various substrates. It also provides good mechanical strength and temperature resistance.

How is DURF1040CT applied in technical solutions?

- DURF1040CT is commonly used in applications such as bonding power semiconductor devices, LED modules, and other electronic components to heat sinks or housings to improve thermal management.

What are the benefits of using DURF1040CT in technical solutions?

- Using DURF1040CT helps to enhance thermal performance, prolong the lifespan of electronic components, and improve overall system reliability by effectively dissipating heat.

Can DURF1040CT be used in high-temperature environments?

- Yes, DURF1040CT is designed to withstand high temperatures, making it suitable for use in applications where heat dissipation is critical.

Is DURF1040CT compatible with different types of substrates?

- Yes, DURF1040CT exhibits good adhesion to various substrates including metals, ceramics, and plastics, making it versatile for different technical solutions.

What is the typical application process for DURF1040CT?

- The typical application process involves cutting the tape to size, removing the release liner, and carefully applying it to the designated surfaces, ensuring proper alignment and pressure for optimal adhesion.

Does DURF1040CT require any special surface preparation before application?

- It is recommended to clean and degrease the bonding surfaces to ensure maximum adhesion and performance of DURF1040CT.

Are there any safety considerations when handling DURF1040CT?

- Users should refer to the product's safety data sheet for specific handling and storage guidelines, as well as any necessary precautions to take during application.

Where can I obtain technical support or further information about DURF1040CT?

- For technical support and additional information about DURF1040CT, you can contact the manufacturer's customer service or visit their official website for documentation and resources.