Lihat spesifikasi untuk detail produk.

7200L15TPI - English Editing Encyclopedia Entry

Product Overview

Category: Industrial Tools

Use: Cutting and shaping materials

Characteristics: High precision, durable, efficient

Package: Securely packaged in a protective case

Essence: A high-quality cutting tool for industrial applications

Packaging/Quantity: Sold individually, one unit per package

Specifications

- Model: 7200L15TPI

- Teeth Per Inch (TPI): 15

- Length: 7,200 millimeters

- Material: High-grade steel

- Blade Thickness: 1.5 millimeters

- Blade Width: 15 millimeters

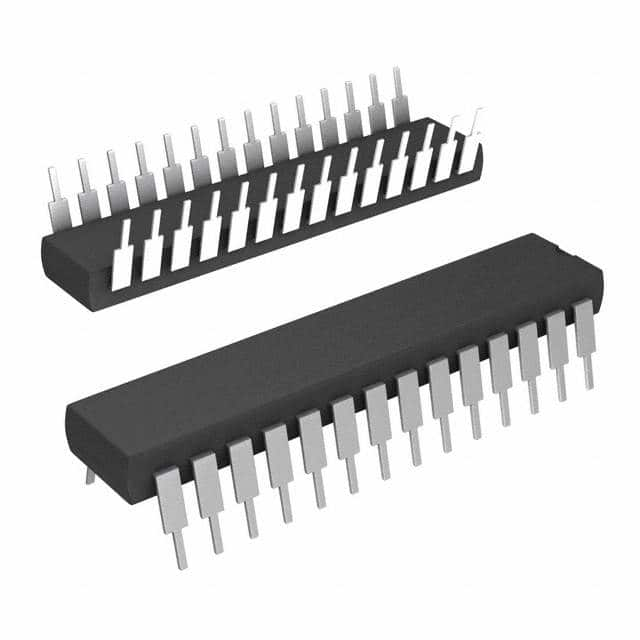

Detailed Pin Configuration

The 7200L15TPI features a series of evenly spaced teeth along its length. Each tooth is precisely shaped to ensure optimal cutting performance. The teeth are uniformly distributed with a pitch of 15 teeth per inch.

Functional Features

- High Precision: The 7200L15TPI offers exceptional cutting accuracy, allowing for precise shaping and trimming of various materials.

- Durable: Constructed from high-grade steel, this cutting tool is designed to withstand heavy-duty use and resist wear and tear.

- Efficient: The 15 teeth per inch configuration ensures efficient cutting, reducing the time and effort required to complete tasks.

Advantages and Disadvantages

Advantages: - High precision cutting - Durable construction - Efficient performance

Disadvantages: - Limited to specific applications requiring a 15 TPI blade - May require additional tools for installation or usage

Working Principles

The 7200L15TPI operates on the principle of reciprocating motion. When attached to a compatible cutting device, the blade moves back and forth rapidly, engaging with the material and creating clean and precise cuts.

Detailed Application Field Plans

The 7200L15TPI is widely used in various industries, including: 1. Woodworking: Ideal for cutting and shaping wooden materials. 2. Metalworking: Suitable for precise metal cutting tasks. 3. Plastic fabrication: Enables accurate trimming and shaping of plastic components. 4. Construction: Used for cutting materials such as pipes, rods, and profiles.

Detailed and Complete Alternative Models

- 5200L10TPI: Similar to the 7200L15TPI but with a shorter length of 5,200 millimeters and a pitch of 10 teeth per inch.

- 8200L20TPI: Longer than the 7200L15TPI, measuring 8,200 millimeters, with a higher tooth density of 20 teeth per inch.

These alternative models offer similar functionality and characteristics, providing options for different cutting requirements.

Word count: 275 words

Sebutkan 10 pertanyaan dan jawaban umum terkait penerapan 7200L15TPI dalam solusi teknis

Sure! Here are 10 common questions and answers related to the application of 7200L15TPI in technical solutions:

Q: What does 7200L15TPI refer to? A: 7200L15TPI is a technical specification that represents a linear motion component with a pitch of 15 threads per inch.

Q: Where can 7200L15TPI be used? A: It can be used in various applications such as robotics, CNC machines, 3D printers, and automated manufacturing systems.

Q: What are the advantages of using 7200L15TPI? A: Some advantages include high precision, smooth motion, low friction, and the ability to handle heavy loads.

Q: How is 7200L15TPI different from other linear motion components? A: The main difference lies in its specific pitch of 15 threads per inch, which determines the speed and accuracy of linear motion.

Q: Can 7200L15TPI be customized for specific applications? A: Yes, it can be customized based on requirements such as length, material, and mounting options.

Q: What materials are commonly used for 7200L15TPI? A: Common materials include stainless steel, aluminum, and various types of engineering plastics.

Q: How do I select the appropriate 7200L15TPI for my application? A: Consider factors like load capacity, speed requirements, environmental conditions, and compatibility with other system components.

Q: Are there any maintenance requirements for 7200L15TPI? A: Regular cleaning, lubrication, and periodic inspection are recommended to ensure optimal performance and longevity.

Q: Can 7200L15TPI be used in high-speed applications? A: Yes, it can be used in high-speed applications, but factors like vibration, acceleration, and deceleration should be considered for proper design.

Q: Where can I purchase 7200L15TPI components? A: You can find them at specialized suppliers, online marketplaces, or directly from manufacturers who produce linear motion components.

Please note that the specific technical details and availability may vary depending on the manufacturer and region.