Lihat spesifikasi untuk detail produk.

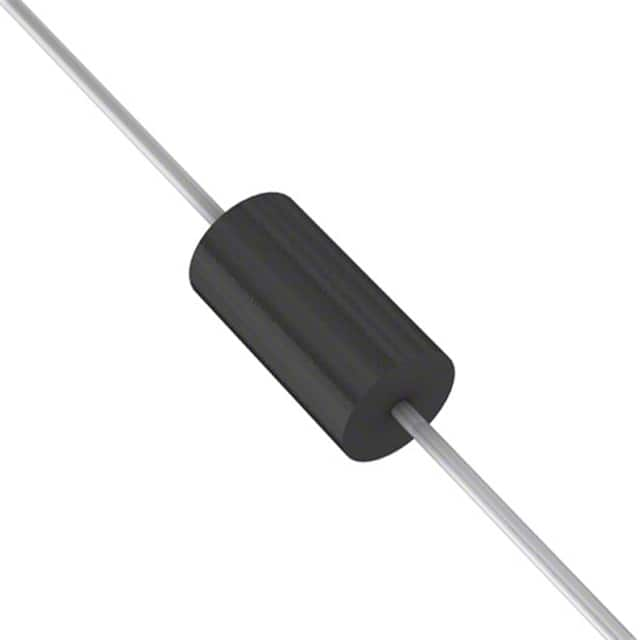

2A05-T Product Overview

Introduction

The 2A05-T is a semiconductor device belonging to the category of diodes. This entry provides an in-depth overview of the 2A05-T, including its basic information, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Diode

- Use: Rectification and voltage regulation

- Characteristics: High current capability, low forward voltage drop

- Package: Through-hole or surface mount

- Essence: Semiconductor material with P-N junction

- Packaging/Quantity: Typically available in reels or tubes containing multiple units

Specifications

- Maximum Forward Voltage Drop: 0.7V

- Maximum Reverse Voltage: 50V

- Maximum Forward Current: 2A

- Operating Temperature Range: -55°C to 150°C

Detailed Pin Configuration

The 2A05-T typically has two pins, anode (A) and cathode (K), with the anode being the positive terminal and the cathode being the negative terminal.

Functional Features

- Efficient rectification of alternating current (AC) to direct current (DC)

- Voltage regulation in electronic circuits

- Fast switching capabilities

Advantages and Disadvantages

Advantages

- Low forward voltage drop reduces power dissipation

- High current capability allows for use in various applications

- Fast response time enhances circuit efficiency

Disadvantages

- Limited reverse voltage tolerance compared to other diode types

- Sensitivity to temperature variations may affect performance in extreme conditions

Working Principles

The 2A05-T operates based on the principle of the P-N junction, allowing current flow in one direction while blocking it in the opposite direction. When forward-biased, it conducts current with minimal voltage drop, making it suitable for rectification and voltage regulation.

Detailed Application Field Plans

The 2A05-T finds extensive use in the following applications: 1. Power supply units 2. Battery charging circuits 3. LED lighting systems 4. Motor drive circuits 5. Solar energy systems

Detailed and Complete Alternative Models

Several alternative models to the 2A05-T include: - 1N5408 - FR207 - 6A10 - 1N5822 - UF4007

In conclusion, the 2A05-T diode offers efficient rectification and voltage regulation capabilities, making it a versatile component in various electronic applications.

Word Count: 324

Sebutkan 10 pertanyaan dan jawaban umum terkait penerapan 2A05-T dalam solusi teknis

Sure, here are 10 common questions and answers related to the application of 2A05-T in technical solutions:

Question: What is 2A05-T?

Answer: 2A05-T is a type of aluminum alloy with good strength and corrosion resistance properties.Question: What are the typical applications of 2A05-T?

Answer: 2A05-T is commonly used in aerospace components, structural parts, and marine equipment due to its high strength-to-weight ratio and corrosion resistance.Question: What are the mechanical properties of 2A05-T?

Answer: 2A05-T typically exhibits high tensile strength, good fatigue resistance, and moderate machinability.Question: Can 2A05-T be welded?

Answer: Yes, 2A05-T can be welded using various techniques such as TIG (tungsten inert gas) welding and MIG (metal inert gas) welding.Question: Is 2A05-T suitable for use in high-temperature environments?

Answer: While 2A05-T has good heat resistance, it may not be ideal for prolonged exposure to very high temperatures.Question: What surface treatments are compatible with 2A05-T?

Answer: Anodizing, painting, and powder coating are common surface treatments for 2A05-T to enhance its appearance and corrosion resistance.Question: Does 2A05-T exhibit good formability?

Answer: Yes, 2A05-T can be formed using conventional methods such as rolling, extrusion, and forging.Question: Are there any limitations to the use of 2A05-T in certain environments?

Answer: 2A05-T may not be suitable for applications involving strong alkaline or acidic environments without proper protective measures.Question: What are the comparative advantages of 2A05-T over other aluminum alloys?

Answer: 2A05-T offers a balance of strength, corrosion resistance, and weldability, making it suitable for a wide range of technical solutions.Question: How does the cost of 2A05-T compare to other materials?

Answer: While the cost of 2A05-T may vary, it generally offers a cost-effective solution compared to some high-performance alloys while still providing desirable properties for many technical applications.