Lihat spesifikasi untuk detail produk.

HCPL-7510-000E

Product Overview

Category

HCPL-7510-000E belongs to the category of optocouplers or optoisolators.

Use

Optocouplers are electronic devices that enable the transfer of electrical signals between two isolated circuits using light. They are commonly used to provide electrical isolation and noise reduction in various applications.

Characteristics

- Provides electrical isolation between input and output circuits

- Transfers signals using light, eliminating the need for direct electrical connection

- Offers high voltage isolation and noise immunity

- Can be used in both analog and digital applications

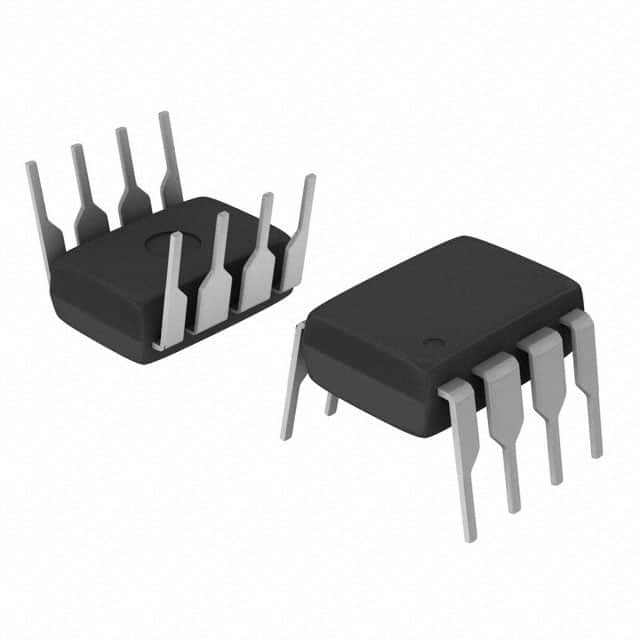

Package

HCPL-7510-000E is available in a compact dual-inline package (DIP) with 8 pins.

Essence

The essence of HCPL-7510-000E lies in its ability to transmit electrical signals across an isolation barrier using an LED and a photodetector. This ensures safe and reliable signal transmission in applications where electrical isolation is crucial.

Packaging/Quantity

HCPL-7510-000E is typically packaged in reels or tubes and is available in quantities suitable for both prototyping and production purposes.

Specifications

- Isolation Voltage: 5000 Vrms

- Input Current: 10 mA

- Output Voltage: 5 V

- Operating Temperature Range: -40°C to +85°C

- Maximum Data Rate: 1 Mbps

Pin Configuration

HCPL-7510-000E features the following pin configuration:

Pin 1: Anode (LED)

Pin 2: Cathode (LED)

Pin 3: NC (No Connection)

Pin 4: GND (Ground)

Pin 5: VCC (Power Supply)

Pin 6: VO (Output Voltage)

Pin 7: NC (No Connection)

Pin 8: NC (No Connection)

Functional Features

- High-speed data transmission

- Wide operating temperature range

- Low power consumption

- Compact and reliable design

- High voltage isolation

Advantages and Disadvantages

Advantages

- Provides electrical isolation, protecting sensitive components from high voltages or noise

- Enables communication between circuits with different ground potentials

- Offers high-speed data transmission capabilities

- Compact size allows for easy integration into various applications

Disadvantages

- Limited maximum data rate compared to some other optocoupler models

- Requires additional circuitry for proper operation

Working Principles

HCPL-7510-000E consists of an LED (Light Emitting Diode) on the input side and a photodetector on the output side. When an electrical signal is applied to the input LED, it emits light. This light is then detected by the photodetector on the output side, which generates a corresponding electrical signal. The input and output sides are electrically isolated, ensuring that any potential difference or noise on one side does not affect the other.

Detailed Application Field Plans

HCPL-7510-000E finds applications in various fields, including:

- Industrial automation: Used for isolating control signals in motor drives, power supplies, and PLCs.

- Telecommunications: Ensures safe signal transmission in telecom equipment, such as modems and routers.

- Medical devices: Provides electrical isolation in patient monitoring systems and medical equipment.

- Automotive electronics: Used in electric vehicles, hybrid vehicles, and automotive control systems for signal isolation and noise reduction.

- Power electronics: Enables isolation in inverters, converters, and power supplies.

Detailed and Complete Alternative Models

- HCPL-4502: Optocoupler with higher isolation voltage and faster data rate.

- HCPL-2630: Optocoupler with lower power consumption and wider temperature range.

- HCPL-7800: Optocoupler with enhanced noise immunity and higher common-mode rejection ratio.

These alternative models offer similar functionality to HCPL-7510-000E but may have different specifications or additional features based on specific application requirements.

In conclusion, HCPL-7510-000E is an optocoupler that provides electrical isolation and enables safe signal transmission in various applications. Its compact design, high voltage isolation, and wide operating temperature range make it suitable for use in industrial automation, telecommunications, medical devices, automotive electronics, and power electronics. While it has certain limitations, such as a limited maximum data rate, there are alternative models available to meet specific application needs.

Sebutkan 10 pertanyaan dan jawaban umum terkait penerapan HCPL-7510-000E dalam solusi teknis

Sure! Here are 10 common questions and answers related to the application of HCPL-7510-000E in technical solutions:

Q: What is HCPL-7510-000E? A: HCPL-7510-000E is a high-speed optocoupler designed for use in industrial applications, providing electrical isolation between input and output.

Q: What is the maximum data rate supported by HCPL-7510-000E? A: The maximum data rate supported by HCPL-7510-000E is typically 15 Mbps.

Q: Can HCPL-7510-000E be used for voltage level shifting? A: Yes, HCPL-7510-000E can be used for voltage level shifting as it provides galvanic isolation between input and output.

Q: What is the typical operating voltage range for HCPL-7510-000E? A: The typical operating voltage range for HCPL-7510-000E is from 4.5V to 20V.

Q: Is HCPL-7510-000E suitable for high-noise environments? A: Yes, HCPL-7510-000E is designed to operate reliably in high-noise environments due to its high common-mode rejection ratio (CMRR).

Q: Can HCPL-7510-000E be used for motor control applications? A: Yes, HCPL-7510-000E can be used for motor control applications as it provides isolation between the control circuitry and the power stage.

Q: Does HCPL-7510-000E have built-in protection features? A: Yes, HCPL-7510-000E has built-in protection features such as undervoltage lockout (UVLO) and overtemperature shutdown.

Q: What is the typical propagation delay of HCPL-7510-000E? A: The typical propagation delay of HCPL-7510-000E is around 100 ns.

Q: Can HCPL-7510-000E be used in high-temperature environments? A: Yes, HCPL-7510-000E can operate in high-temperature environments as it has a wide operating temperature range of -40°C to +100°C.

Q: Is HCPL-7510-000E RoHS compliant? A: Yes, HCPL-7510-000E is RoHS compliant, meaning it does not contain any restricted substances according to the RoHS directive.

Please note that these answers are general and may vary depending on the specific application and requirements. It is always recommended to refer to the datasheet and consult with the manufacturer for detailed information.