Lihat spesifikasi untuk detail produk.

UDN2982A-T

Product Overview

Category

UDN2982A-T belongs to the category of integrated circuits (ICs).

Use

This product is commonly used as a high-voltage, high-current source driver. It is designed to control inductive loads such as relays, solenoids, and stepper motors.

Characteristics

- High-voltage capability: UDN2982A-T can handle voltages up to 50V.

- High-current capacity: It can drive currents up to 500mA per channel.

- Thermal shutdown protection: The IC includes built-in thermal shutdown circuitry to prevent overheating.

- Low power consumption: UDN2982A-T operates at low power levels, making it energy-efficient.

- Fast switching speed: It offers fast switching times for precise control of inductive loads.

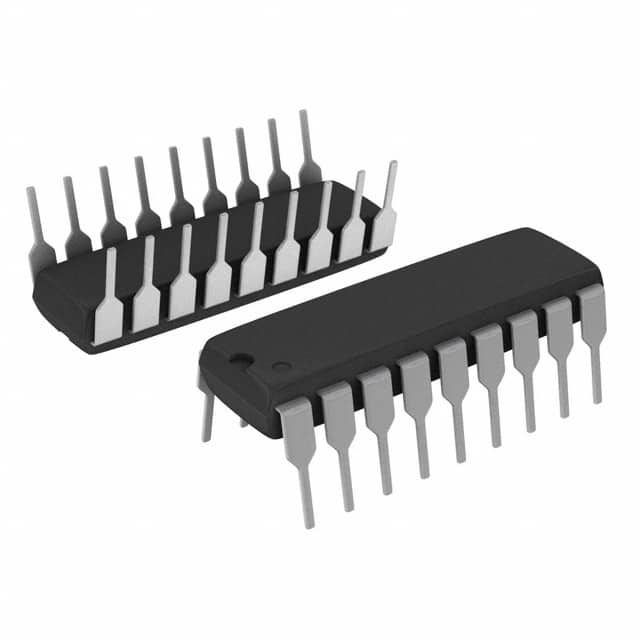

Package

UDN2982A-T is available in a 16-pin dual in-line package (DIP). This package provides easy mounting and soldering onto printed circuit boards (PCBs).

Essence

The essence of UDN2982A-T lies in its ability to provide reliable and efficient control over high-voltage and high-current inductive loads.

Packaging/Quantity

UDN2982A-T is typically packaged in reels or tubes, with each reel or tube containing a specific quantity of ICs. The exact packaging and quantity may vary depending on the supplier.

Specifications

- Supply Voltage Range: 5V - 50V

- Output Current: Up to 500mA per channel

- Number of Channels: 8

- Operating Temperature Range: -40°C to +85°C

- Input Logic Compatibility: TTL, CMOS

Detailed Pin Configuration

UDN2982A-T features a 16-pin DIP package with the following pin configuration:

- Output Channel 1

- Output Channel 2

- Output Channel 3

- Output Channel 4

- Output Channel 5

- Output Channel 6

- Output Channel 7

- Output Channel 8

- Ground (GND)

- Input Channel 1

- Input Channel 2

- Input Channel 3

- Input Channel 4

- Input Channel 5

- Input Channel 6

- Input Channel 7

Functional Features

- High-voltage and high-current capability for driving inductive loads.

- Built-in thermal shutdown protection to prevent overheating.

- Fast switching speed for precise control.

- TTL and CMOS compatible input logic.

Advantages and Disadvantages

Advantages

- Suitable for controlling a wide range of inductive loads.

- Can handle high voltages and currents.

- Offers thermal shutdown protection.

- Energy-efficient operation.

- Fast switching times for accurate control.

Disadvantages

- Limited number of channels (8).

- Requires external power supply.

Working Principles

UDN2982A-T operates by receiving input signals from a microcontroller or other control circuitry. These input signals determine the state of each output channel, which in turn controls the corresponding inductive load. The IC's internal circuitry ensures that the output channels can handle high voltages and currents while providing fast switching speeds.

Detailed Application Field Plans

UDN2982A-T finds applications in various fields where precise control of inductive loads is required. Some common application areas include:

- Industrial Automation: Controlling solenoid valves, relays, and stepper motors in manufacturing processes.

- Robotics: Driving motors and actuators in robotic systems.

- Automotive: Controlling automotive relays and motors.

- Home Automation: Operating appliances and devices with inductive loads.

- Medical Equipment: Driving pumps, valves, and motors in medical devices.

Detailed and Complete Alternative Models

- UDN2981A-T: Similar to UDN2982A-T but with 7 output channels instead of 8.

- ULN2803A: A popular alternative with 8 output channels and built-in flyback diodes for inductive load protection.

- L293D: Dual H-bridge motor driver IC suitable for driving DC motors and stepper motors.

These alternative models offer similar functionality and can be used as substitutes for UDN2982A-T depending on specific requirements.

In conclusion, UDN2982A-T is a versatile integrated circuit designed for controlling high-voltage and high-current inductive loads. With its fast switching speed, thermal shutdown protection, and compatibility with various input logic levels, it finds applications in diverse fields such as industrial automation, robotics, automotive, home automation, and medical equipment.

Sebutkan 10 pertanyaan dan jawaban umum terkait penerapan UDN2982A-T dalam solusi teknis

Sure! Here are 10 common questions and answers related to the application of UDN2982A-T in technical solutions:

Question: What is UDN2982A-T?

Answer: UDN2982A-T is a high-voltage, high-current source driver IC used for driving relays, solenoids, and other high-power loads.Question: What is the maximum voltage rating of UDN2982A-T?

Answer: The maximum voltage rating of UDN2982A-T is 50V.Question: What is the maximum current rating of UDN2982A-T?

Answer: The maximum current rating of UDN2982A-T is 500mA per channel.Question: How many channels does UDN2982A-T have?

Answer: UDN2982A-T has 8 channels, allowing you to control up to 8 different loads.Question: Can UDN2982A-T be used with microcontrollers?

Answer: Yes, UDN2982A-T can be easily interfaced with microcontrollers or other digital logic circuits.Question: Does UDN2982A-T require external components for operation?

Answer: Yes, UDN2982A-T requires external diodes and capacitors for proper operation.Question: What is the input voltage range for UDN2982A-T?

Answer: The input voltage range for UDN2982A-T is typically between 3V and 5V.Question: Can UDN2982A-T handle both AC and DC loads?

Answer: Yes, UDN2982A-T can handle both AC and DC loads, making it versatile for various applications.Question: Is UDN2982A-T suitable for automotive applications?

Answer: Yes, UDN2982A-T is designed to withstand the harsh conditions of automotive environments.Question: Can UDN2982A-T be used in industrial automation systems?

Answer: Absolutely! UDN2982A-T is commonly used in industrial automation systems for controlling high-power devices.

Please note that these answers are general and may vary depending on specific application requirements.